Cable tie performance is directly related to the moisture content of the ties. Nylon 6/6 is the material of choice for cable ties for many reasons. With a very high strength to weight ratio, this material is noted for its toughness, impact strength, resistance to abrasion and chemicals, wide temperature range, and versatility in a variety of applications. Nylon 6/6 is a naturally hydroscopic materials – it absorbs and releases moisture depending on its environment.

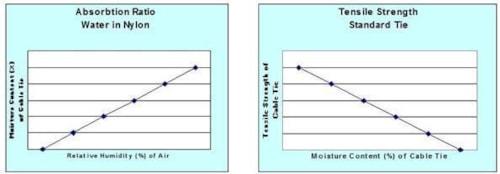

When first produced, cable ties contain nearly zero per cent moisture. At this point, the ties are at their greatest tensile strength but may also be brittle and lack toughness. If exposed to air for an extended period of time, the tie will naturally absorb water. However, this can take several weeks. Where the average relative humidity is about 60%, a normal condition in the United States, the tie will reach about 3% moisture. Figure A of the graph below indicates how relative humidity affects the amount of moisture.

Manufacturers of cable ties, however, want the ties to reach an optimal condition quickly so a measured quantity of water (2-3% by weight) is added during the packaging process. Following the addition of this moisture, it takes about three weeks for the desired level of absorption to take place for optimal performance. Resulting from this procedure is a fine balance between tensile strength and toughness. Figure B of the graph below highlights how the tensile strength decreases with increased moisture and further emphasizes the value of a 2-3% moisture content for cable ties (in this case, this relationship is illustrated for a standard 50 lb tie).

Figure A – Absorption Ratio Figure B – TensileStrength

When examining concerns regarding the performance of cable ties, it is clearly evident that moisture is often the issue. Following the recommendations below will minimize this issue and maximize performance.

- Bags of ties should be used in a timely manner or remain sealed until required for application. Bags left open result in ties drying out, becoming brittle, and perhaps breaking.

- Proper quantity per bag should be purchased – bulk bags are ideal for higher volume usage while smaller bags are recommended for low volume requirements.

- A first in first out inventory policy, as we do at Cable Tie Express, is recommended.

- Special attention regarding usage and storage environments is recommended during times of the year when extreme temperatures exist.

We hope this information is helpful in your understanding of cable ties and their performance. We provide this to you in keeping with our Mission Statement - to be the most responsive, dependable, and knowledgeable provider of superior quality cable ties and associated products. Please contact the Sales Professionals at Cable Tie Express for further information.

Related Topics: Cable Clamps, Cable Management, Cable Management Ideas, Cable Tie Supplier, Cable Tie Uses, Cable Ties, Tie Wraps, Moisture